AI-Driven Innovations in Electric Car Manufacturing

The electric vehicle (EV) industry is evolving at an unprecedented pace, and artificial intelligence (AI) is at the heart of this transformation. AI is no longer just about self driving cars it’s revolutionizing manufacturing, battery technology, safety features, and supply chain management, making EVs smarter, more efficient, and more sustainable.

Companies like Tesla, BYD, Rivian, Volkswagen, and General Motors are at the forefront, using AI to automate production lines, optimize battery life, and develop cutting edge driver assistance systems. From predictive analytics that reduce factory downtime to machine learning models that enhance driving experiences, AI is reshaping the way EVs are designed, built, and used.

This blog explores how AI is changing the landscape of EV manufacturing, compares how leading automakers use AI in their operations, highlights the advantages and challenges of AI adoption.

1. The Role of AI in Electric Vehicle Manufacturing

AI has become an essential part of modern EV manufacturing, helping automakers reduce production costs, improve quality control, enhance battery efficiency, and streamline logistics. Here’s a closer look at the key areas where AI is supporting lean manufacturing goals and making an impact.

AI in Production and Automation

Manufacturing an EV is a complex process involving thousands of components and precision engineering overseen by production management software. AI and ML model deployment is helping automakers speed up production while improving accuracy and reducing defects.

- AI powered robots assemble cars with incredible precision, handling delicate tasks like welding, painting, and even installing tiny electronic components like an accelerator card.

- AI-driven predictive maintenance identifies issues with machinery before they cause disruptions, preventing costly delays in production.

- Computer vision systems inspect every detail of a vehicle to detect defects in real-time, ensuring quality standards are met.

AI in Battery Management and Optimization

Batteries are the heart of an EV, and AI is making them smarter and more efficient.

- Machine learning algorithms analyze charging patterns(via the OCPP Gateway), driving habits, and environmental factors to optimize battery health.

- AI helps develop next generation batteries by running simulations to test new materials and energy storage solutions.

- Smart battery management systems predict degradation rates, helping owners maximize battery life while reducing waste.

AI in Autonomous Driving and Advanced Driver Assistance Systems (ADAS)

Self driving technology gets a lot of attention, but even without full autonomy, AI is already making cars safer and smarter.

- Tesla’s Full Self-Driving (FSD) and GM’s Cruise AV rely on neural networks to process data from cameras, radar, and LiDAR sensors, allowing them to navigate roads with minimal human input.

- AI enhances adaptive cruise control, lane departure warnings, automatic emergency braking, and obstacle detection, making driving safer.

- AI powered logistics track shipments in real time, reducing delays and optimizing distribution networks. Businesses are also beginning to integrate automated AI phone calls or outsourced call centers (after consultation with experts like TDS Global Solutions) and communicate faster with partners.

AI in Supply Chain and Logistics

Building an EV requires a massive global supply chain, and AI is helping manufacturers keep things running smoothly.

- AI forecasts demand, ensuring factories have the right materials at the right time.

- Automated warehouses use AI driven robots to manage inventory and pack orders efficiently.

- AI powered logistics track shipments in real time, reducing delays and optimizing distribution networks.

2. AI-Powered Electric Car Manufacturers: A Comparative Overview

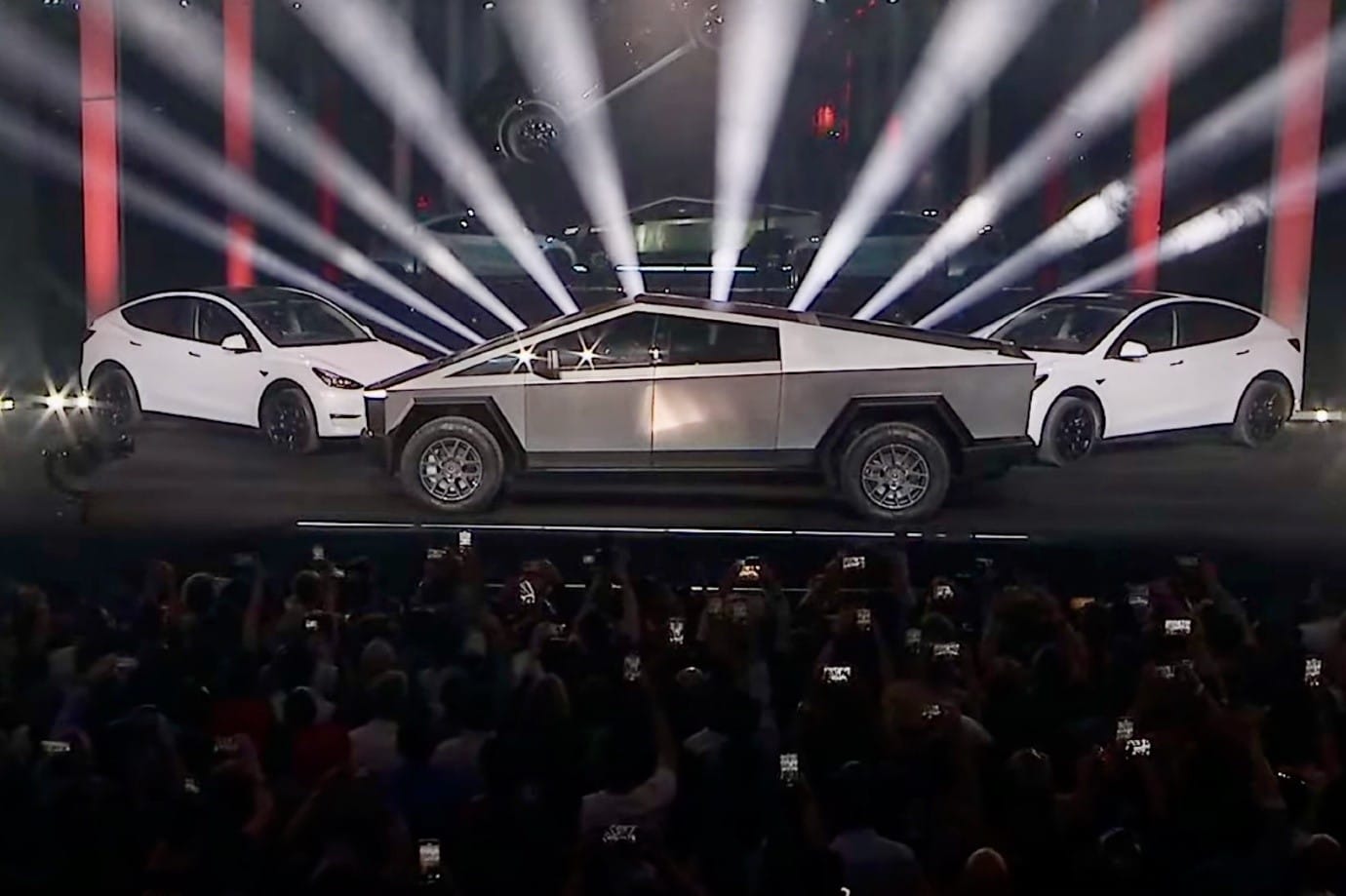

Tesla: AI at the Core of EV Innovation

Tesla is a pioneer in AI driven electric vehicles, using AI across self driving technology, manufacturing, and battery management.

- Tesla’s Full Self Driving (FSD) relies on deep learning and real-time road data from millions of Tesla vehicles.

- AI driven Gigafactories use robotic automation to improve production speed and quality.

- The 4680 battery cells, developed using AI, increase range and durability while lowering costs.

- AI helps Tesla’s supply chain run efficiently, predicting material shortages and optimizing logistics.

BYD: China’s AI-Driven EV Powerhouse

BYD is one of the world’s biggest EV manufacturers, using AI to enhance efficiency and safety.

- The Blade Battery, developed with AI simulations, is one of the safest EV batteries available.

- AI powered robotic arms handle vehicle assembly, reducing labor costs and improving precision.

- AI driven driver assistance features improve lane keeping, collision detection, and energy consumption.

- Fleet management AI helps logistics companies reduce fuel consumption and improve scheduling in order to reduce costs, as the best fuel cards for small business do.

Rivian: AI-Powered Adventure Vehicles

Rivian is redefining the electric adventure vehicle market by using AI for off road driving, predictive analytics, and fleet monitoring.

- AI powered adaptive suspension adjusts in real-time for better off road capability.

- AI enhances regenerative braking, recovering more energy based on road conditions and driver behavior.

- AI driven battery management systems analyze driving habits to optimize range and performance.

Volkswagen: AI and Digitalization for the Next Generation of EVs

Volkswagen is integrating AI into its Project Trinity, a new software defined EV platform that evolves with over the air updates.

- Industrial AI powered automated assembly lines improve efficiency and reduce production costs.

- AI driven predictive safety features enhance hazard detection and emergency braking.

- AI improves sustainability efforts by optimizing battery recycling and carbon reduction in manufacturing.

General Motors (GM): AI in Battery Technology and Self-Driving Development

GM is using AI to advance battery efficiency, self driving vehicles, and factory automation.

- The Ultium battery platform, developed using AI, maximizes energy output and battery lifespan.

- GM’s Cruise AV division is testing fully self-driving electric cars in urban environments.

- AI powered factory systems predict machine failures before they happen, reducing downtime.

3. Comparative Table of AI-Driven EV Technologies

Feature | Tesla Model Y | BYD Seal | Rivian R1T | Volkswagen ID.4 | GM Ultium EVs |

AI in Self-Driving | Full Self-Driving (Beta) | Partial AI Assistance | Advanced ADAS | Basic ADAS | AI in Cruise AV |

Battery Technology | 4680 Cells (AI-Optimized) | Blade Battery (AI-Enhanced) | AI-Managed Lithium Battery | Lithium-Ion (AI-Optimized) | Ultium Battery (AI-Enhanced) |

AI in Manufacturing | Fully Automated Gigafactory | AI-Assisted Robotics | AI-Based Quality Control | AI in Digitalized Factories | AI in Supply Chain Management |

Sustainability AI | AI-Driven Battery Recycling | AI for Energy Optimization | AI in Regenerative Braking | AI for Carbon-Neutral Production | AI in Material Sourcing |

4. How CodeDesign Supports the Automobile Industry

CodeDesign is helping automotive brands leverage AI for a smarter, more engaging digital presence.

- AI Powered Websites and UI/UX Solutions

- Interactive, AI driven websites for EV brands.

- AI powered chatbots that assist customers in selecting the perfect EV.

- Predictive Analytics for EV Marketing

- AI analyzes market trends, helping EV brands optimize advertising.

- AI-driven lead generation improves sales conversion rates.

- AI in Fleet Management and IoT Integration

- AI based monitoring of EV performance, battery life, and predictive maintenance.

- Optimized routing and real-time vehicle tracking for commercial fleets.

5. Conclusion: The Future of AI in Electric Vehicles

The future of electric vehicles is AI driven. From self driving technology to smart batteries and automated factories, AI is shaping the next generation of mobility. Companies that embrace AI-powered automation, machine learning, and predictive analytics will lead the industry in efficiency, innovation, and sustainability.

Reference